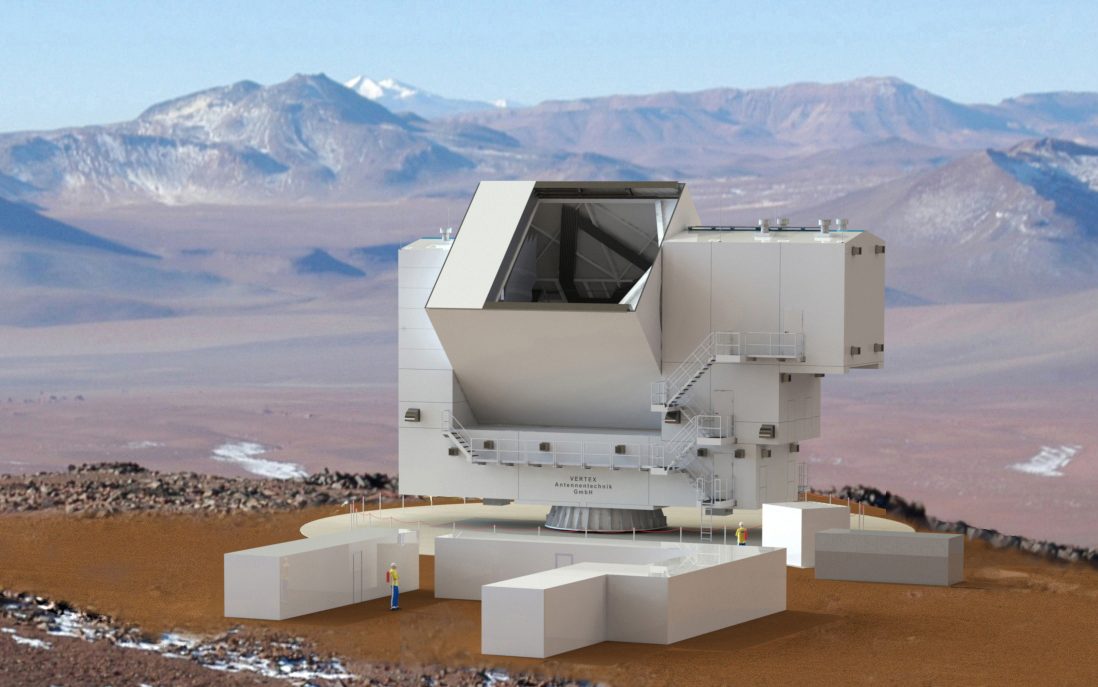

I led the mechanical design team of 6 Cornell undergraduate and graduate students on the wall-climbing robot project for the CCAT-prime telescope (Later renamed Fred Young Submilimeter Telescope – FYST). The CCAT-prime is a submilimeter telescope being constructed on Cerro Chjnantor, expecting to be completed in 2024.

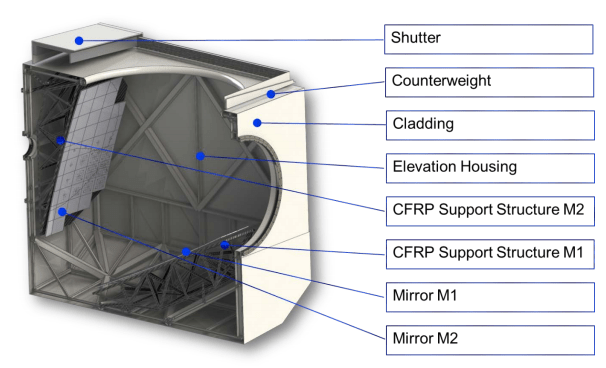

The CCAT-prime is comprised of two 6-meter diameter aluminum mirror surfaces that are approximately 70 degrees from each other. The entire mirror chamber is designed to rotate, so both mirrors can become vertical and even overhanging. Each mirror surface is made of around 80 individual panels, each with four actuators behind its surface for orientation control. The precise alignment of each of the panels in each mirrors is critical to the function of the telescope, and displacements from thermal effects and chamber rotation necessitate metrology assistance for proper mirror panel alignment.

Our team’s goal was to design an autonomous robot that would be able to safely maneuver the mirrors, while taking positional measurements at various points of each panel to assist in mirror panel alignment. The characteristics of the aluminum panels doesn’t allow direct laser measurement of the surface position, so a specialized retro-reflector is used to take measurements of the mirror. The two major design components of this project were the wall-climbing robot chassis design, and the panel position measurement design.

Wall-climbing robot chassis design

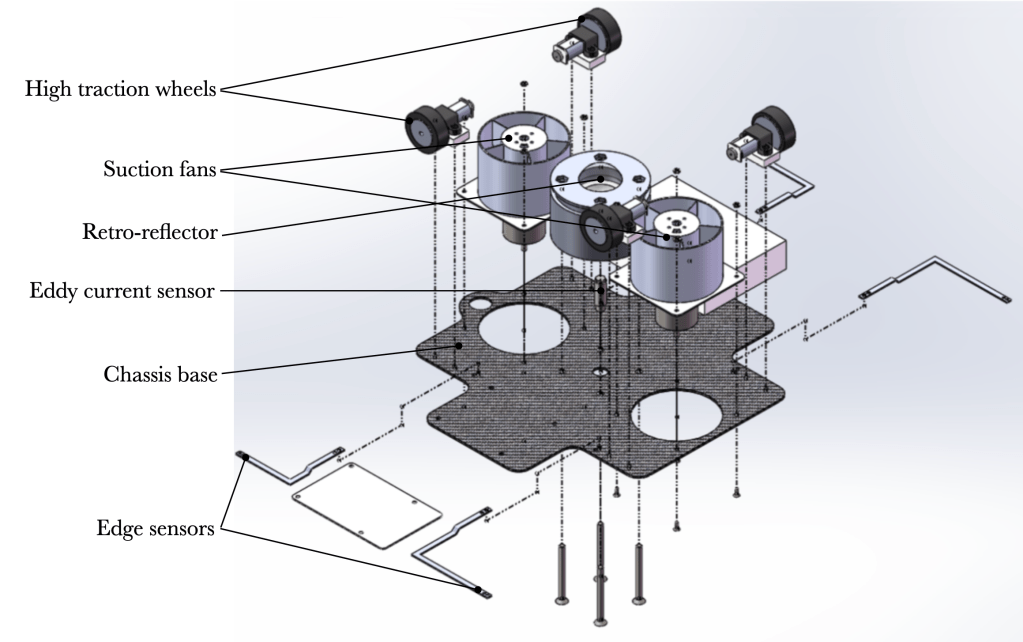

I explored several different climbing methods for the robot, including an electromagnetic robot, sticky feet robot, and suction cup robot. Ultimately, we determined that a fan-powered climbing method would be optimal for our application. In our robot design, there are two powerful fans that drive the robot into the wall, while creating a suction underneath the robot chassis. Combined with the suction force driving the robot into the panel surface and the high traction wheels that provide lateral stability, the robot is able to reliably maneuver the mirror surface at any orientation.

Mirror panel position measurement design

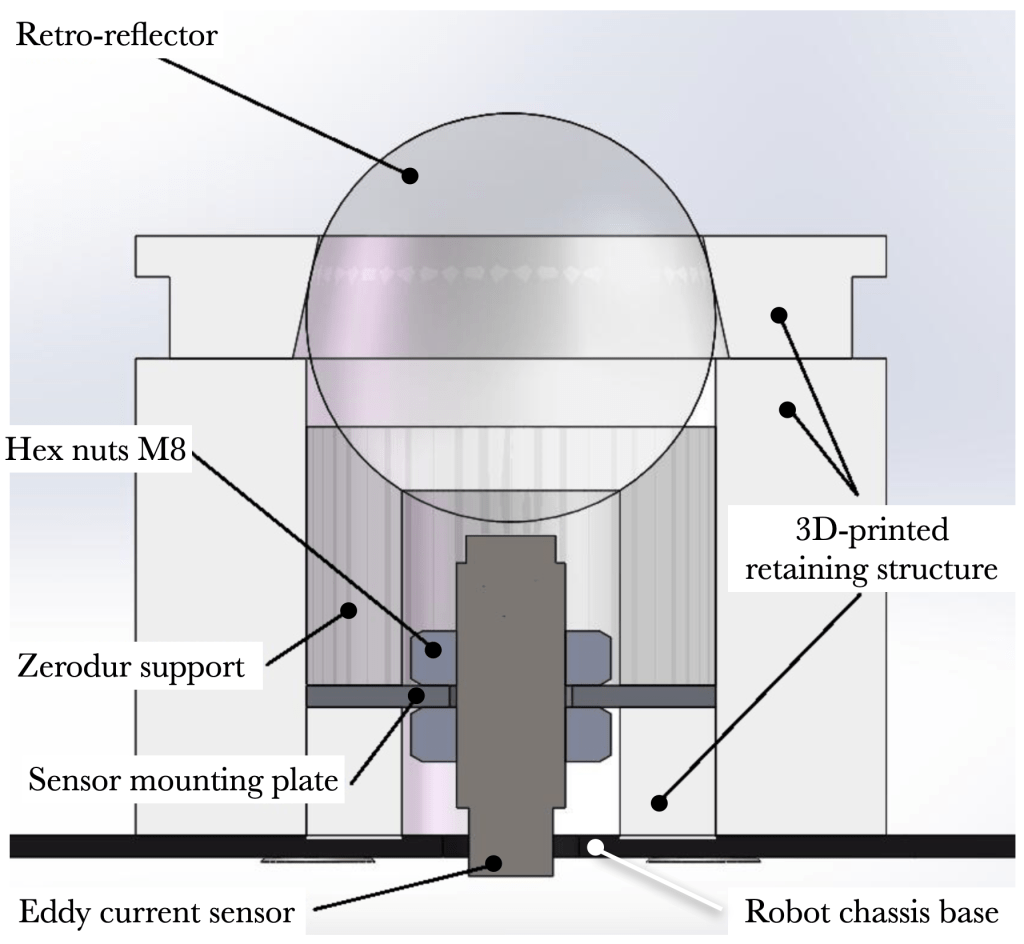

The robot assists in mirror panel alignment by placing the retro-reflector at several points on each panel, allowing a separate laser measurement system to triangulate the location of the retro-reflector. If the robot is able to provide the normal distance between the retro-reflector and the mirror panel surface, we can calculate the orientation of each panel and give commands to the panel actuators to correct any misalignment.

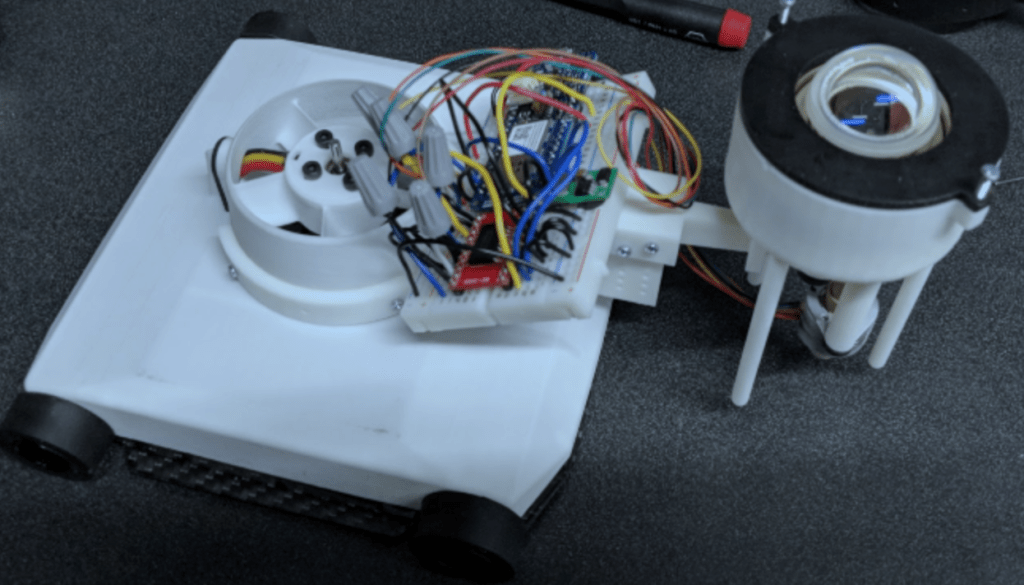

My first prototype of the robot included an arm attachment for the retro-reflector, which would be lifted off of the panel surface while driving, and would actuate down to make contact with the panel surface during measurement. The retro-reflector sat on top of 3 legs on the arm attachment, so it would maintain a constant offset from the mirror surface.

There were a few critical shortcomings to first prototype that we aimed to mitigate with our next iteration. First, the arm actuation made the robot unstable when the arm pushed into the panel, and made it more difficult to control the robot with the large offset weight. For the next prototype, we wanted to make a more symmetrical design that would reduce the strain on the robot. Secondly, the physical contact the retro-reflector arm would make with the mirror panel increased risk of damaging the surface of the mirror, and added more error to the measurement if any dust or debris were to be caught under the arm. For the next prototype, we wanted to make a non-contact design for the retro-reflector that would be more robust against dust and debris.

The final robot design improved in all of these areas. The retro-reflector was placed in the center of the robot, with two fans that added stability to the chassis. Instead of the actuated arm design that would touch down on the mirror surface for every measurement, we placed an eddy current sensor, which uses electromagnetic effects to measure the distance to the mirror surface. The eddy current sensor measurements are not affected by dust and other impurities on the surface. The retro-reflector would be secured on top of a Zerodur structure, which has a very small coefficient of thermal expansion. As a result of theses improvements, the robot is able to meet the accuracy requirements while being robust against environmental effects.